PLASTRON 05 K

Metal separator for installation on injection molding machines or extruders

Metal separator for installation on injection molding machines or extruders

in Cleaning and Maintenance

In the field of injection molding and extrusion, the machine uptime and the quality of the end product are the factors that decide between waxing and waning company success. The correct handling of metallic foreign bodies in the production chain, especially for the protection of the processing machines, plays a decisive role here.

Ingress is unavoidable!

Metallic foreign bodies are found in every industrial production process. This applies just as much to the manufacture of foodstuffs and pharmaceuticals as it does to molding processes in the plastics industry. The sources are manifold. Depending on the raw material, contaminants are already introduced in the incoming goods area. This mainly concerns regenerates, but also applies to colour additives or brand new granulates.

The last chance becomes the first choice

Optimised detection performance.

Innovation and reliability meet in the specially developed sensor coil and the proven AMD 05 evaluation electronics. These guarantee stable, maximum performance even in the most demanding injection molding and extrusion environments.

Everything under control.

The standard features of the AMD 05 include password-protected access control and the logging of all system events on the integrated SD card. The system settings are also backed up to this card on a regular basis so that they are simple to restore in case of service.

Ready for Industry 4.0!

With various analog and digital connection options via serial, bus or Ethernet, the PLASTRON systems are equipped for all requirements. Optionally with networking and remote maintenance option.

Detection alone is not enough!

At least as important as good detection performances is the absolutely reliable discharge of the material, even with slumping columns and free-fall or bridge-forming materials. The unique mechanical design and the innovative blow-out principle ensures this even with powdered products or flakes.

Flexibility means future-proof.

Requirements can change, depending on the material used or the production process. With a permissible maximum material temperature of 120 °C and easy to retrofit adaptor plates, you don’t have to worry about the PLASTRON.

Small but resilient.

Despite their compact structure, all devices in the series are extremely sturdy. High vertical loads due to suction conveyors or mixers, as well as vibrations due to the molding process, can easily be absorbed due to the decoupled coil design and the solid mounting frame.

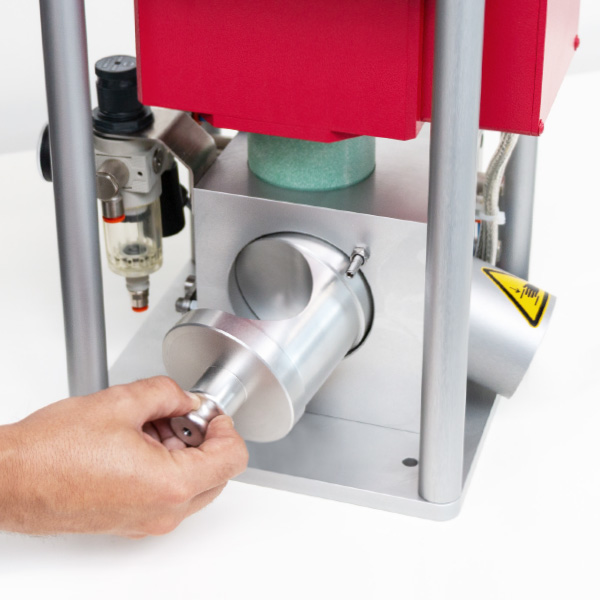

Uncompromising cleanliness!

Changes of colour or material necessitate the residue-free cleaning of system components in modern production environments. The PLASTRON’s ejector has therefore been conceived with no dead spaces and can be dismantled in a matter of seconds without tools.

Maintenance without waiting.

All mechanical attached parts are unobstructed and easy to reach. High-quality components and the monitoring of the system parameters (optionally also the flap function) allow predictive maintenance cycles that can be scheduled. Since all devices from the series use the same components, the maintenance of systems from 30 – 120 mm is very much simplified, as it is virtually identical.

The other money-back guarantee.

The modular device design enables us to include many features such as data storage, maintenance unit or mounting frame in the standard price. In conjunction with the fast cleaning, the reliable ejection and the high precision, we are thus able to achieve very fast amortisation of the acquisition price.

Total security.

In addition to the standard monitoring functions, the compressed air supply and ejector position can optionally also be monitored. All messages are recorded in the log and are optionally only resettable by entering a password.

Just let it run!

For emptying when production is stopped or when changing material and colour, a so-called drain button can also be purchased as an option.

How about an extra connection?

Also available are adaptor plates for the inlet and good material outlet adapted to the most diverse feeding and plastification units.